Hydraulic Specialty Inc

페이지 정보

본문

The components you need, when you want them. Particulars matter. If there’s a component you need, look no additional than Hydraulic Specialty. We have now an entire stock of pumps, motors, valves, telescopic and customized-built cylinders, filters, hose assemblies, seals, fittings and more. Our specialists supply from the highest names in the business. And our wet kits are probably the most dependable you will get. If we don’t carry what you need, simply inform us what you want. We’ll custom make it. There are typically three various kinds of hydraulic motors based on their configuration: piston, gear, and vane. These motors are interchangeable with the identical form of hydraulic pumps when used to pour a fluid where the hydraulic motor acts as a pump acting on exterior torque and vice versa. These can be found in fastened and variable volume versions. The most common kind of motor can be a piston motor called an axial piston pump. These have a high quantity effectivity and are adaptable to numerous loading situations. There are usually two forms of axial piston hydraulic motors, namely bent axis and swish plate. Nevertheless, contemplating the hydraulic motor worth, the bent axis hydraulic motor is often priced larger than the swish plate, the latter nonetheless stays extra prevalent than its alternatives. These motors present moderate effectivity by providing a steady service at rated energy levels.

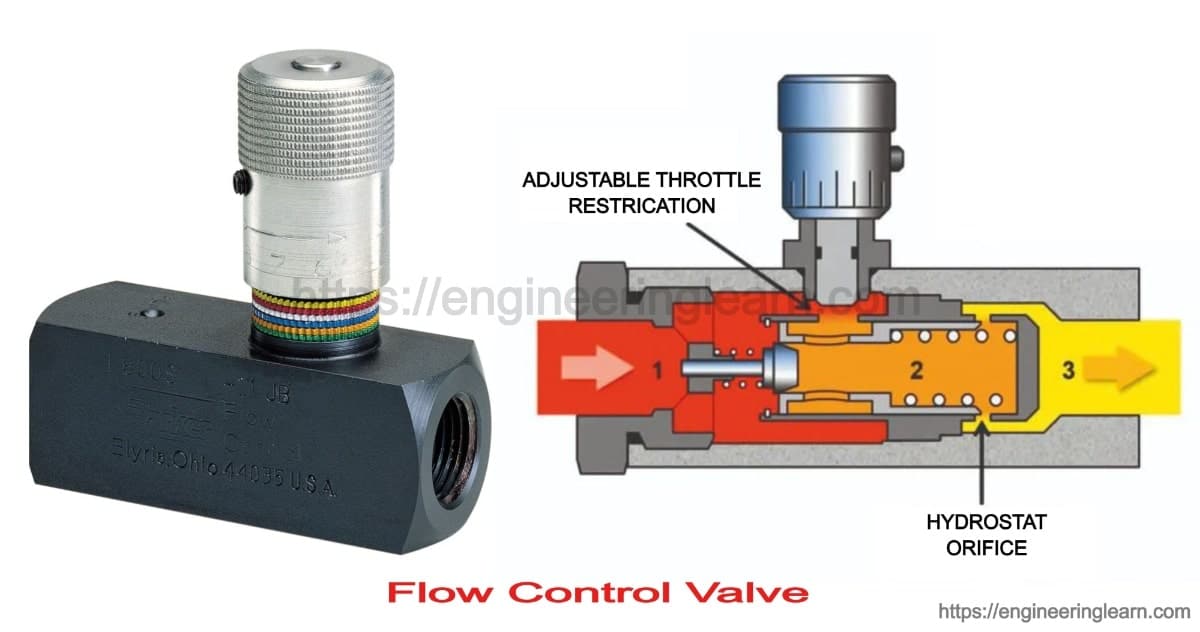

This unit is devoted to every of the following categories of management valves. DCVs management the course of movement in a circuit, which among different things; can control the route of the actuator. PCVs control the pressure stage, which controls the output pressure of a cylinder or the output torque of a motor. FCVs management the flow fee of the fluid which controls the velocity of the actuators. Stress relief valves - Relief valve opens and bypasses fluid when strain exceeds its setting. These are used largely in all circuits. Pressure-Reducing Valve - One of these valve (which is normally open) is used to keep up lowered pressures in specified places of hydraulic systems.

Now, even in closed programs, fluid contamination can come from various inside or external sources, but a standard supply is the air respiratory apparatus within the hydraulic oil tank. When fluid returns from the cylinder to the tank, the breather releases air. If the air outlet channel from the oil tank is restricted or blocked, the internal stress may rise above a safe stage, which can lead to severe leakage. Manufacturers of Pressure Vessels that require certification and testing. Installers of Oil and Gas Pipelines that require testing and certification prior to use. Manufacturers of Tubes, Pipes and Fittings. Manufacturers and Suppliers of Hydraulic (and different types) Hoses. Fireplace Combating Business with the filling of extinguishers with CO2. Refrigeration and Air-Conditioning Business with the evacuating and re-filling of refrigerant techniques. The output fluid circulate is constant and is independent of the system strain (load). The necessary benefit associated with these pumps is that the high-pressure and low-stress areas (means enter and output region) are separated and hence the fluid can not leak again on account of increased stress at the outlets. These options make the optimistic displacement pump most suited and universally accepted for hydraulic systems.

- 이전글Which Website To Research Sports Toto Korea Online 24.10.13

- 다음글Раскрытие силы личной валюты 24.10.13

댓글목록

등록된 댓글이 없습니다.